Process

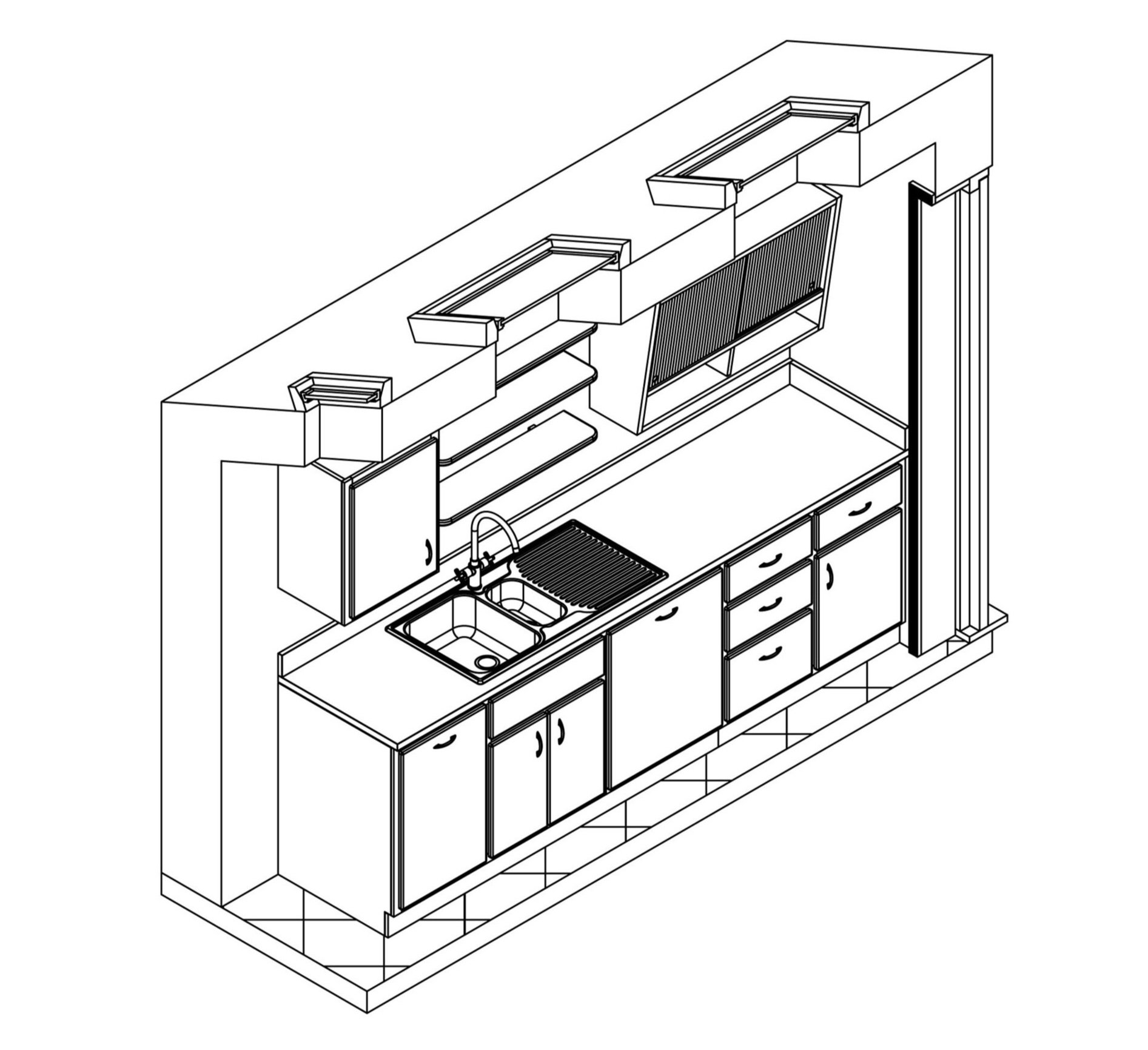

1. Ideations. An initial period of consultation will be arranged to discuss your ideas. This allows us to make a design proposal and formulate a quotation. We dedicate time creating a detailed proposal to ensure a well reasoned and flawless end product.

2. Refinement. The next stage in the process focuses on refinement. We question every single detail, regardless of size, to ensure delivery of a high quality, considered design that will bring you timeless pleasure. We like to think of each of our kitchens as a collection of impeccably designed products. Not only is our workmanship, so are the materials we select, using only high end ironmongery, hinges and drawer runners. Every aspect is carefully considered, we don't cut corners.

Once the layout of the kitchen and design details have been approved we will issue a Service Drawing for your building contactor to amend or install the necessary services for the required appliances.

3. Creation. Hand made to fine tolerances every single cabinet is produced and assembled in our own workshop. Each project is fully assembled (dry fitted) in the workshop to ensure our high standards are maintained, before disassembly and cleaning prior to delivery. Appliances can be organised through our own suppliers, these are also dry fitted before packaging and delivery.

4. Installation. When your space is ready in line with the service drawing, the installation will begin. We are accredited fabricators of Corian® solid surface, or if specified we are able to work with trusted suppliers of natural and manmade stone work surfaces. Standforth delivers a professional, high quality service and we are extremely passionate about what we do.